What is a Pallet Stopper?

Pallet stoppers are used between individual processing stations within transport systems. Most objects transported on small pallets are halted at the processing stations or separated from a convoy.

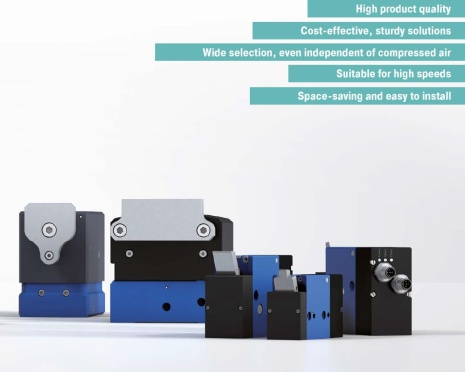

Our compact machine elements operate pneumatically or electrically, with damping provided pneumatically or via integrated ACE shock absorbers. The pneumatic versions offer a choice between single-acting and double-acting separators that function either with or without inductive or electronic monitoring. The electric versions all provide shock-free operation in environments without compressed air.

Transfer Technology Components

Greatest process reliability and cycle stability

ACE pallet stoppers ensure gentle, precise and accurate damping of pallets and workpiece carriers on belt and roller conveyor systems and accumulating roller conveyors. This leaves transported goods and machinery unharmed and optimises process engineering. The high product quality increases speed along with improved longevity and reliability.

Our complete range of pallet stoppers combined with comprehensive accessories guarantees the greatest possible flexibility and maximum compatibility with a multitude of standard transfer systems.

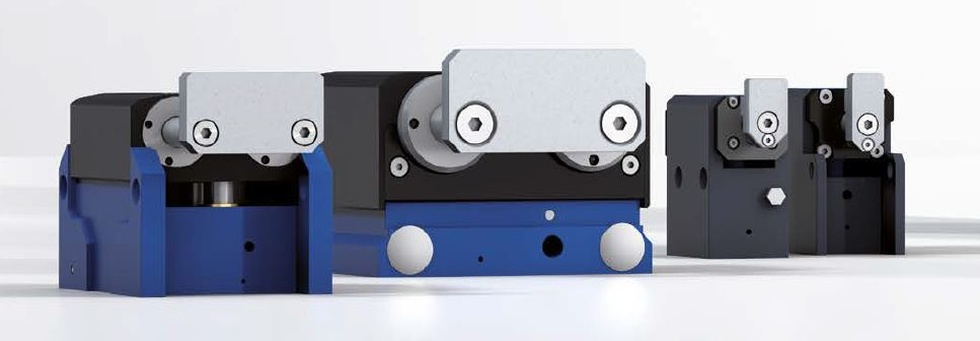

Pneumatic Pallet Stoppers

Gentle deceleration of light to heavy loads

The pneumatic ACE separators are divided into seven product families that cover mass ranges from 1 kg to 1,200 kg. A distinction is made in the case of attenuated products between monitoring options and between single-acting and doubleacting models.

Speed and precise working are the top priority in production. ACE pallet stoppers are the ideal aids whenever workpieces have to be manoeuvred quickly and gently through production. This is because they provide shock-free deceleration of workpiece carriers, bring them to a pinpoint standstill and use pneumatic lowering to release them again to the next processing station after a freely defi nable waiting time – jointly or individually. Pneumatic damping force can be continuously adapted to the weight of the workpiece carrier.

|

P-H1200The largest: gentle and precise with an ACE shock absorber.For heavy workpiece carriers up to 1.2 tons! Pure performance. Our largest pneumatic pallet stopper with integrated ACE shock absorber decelerates even high masses of 40 kg to 1,200 kg extremely effectively. Ideal for transferring sensitive products with significant weight. |

P-P60Our smallest: stops masses between 1 kg and 60 kg These are the smallest of the pneumaticallyoperated damping modules offered by ACE and they reliably stop masses from 1 kg up to 60 kg. They are used whilst manoeuvring sensitive products on transfer systems. |

|

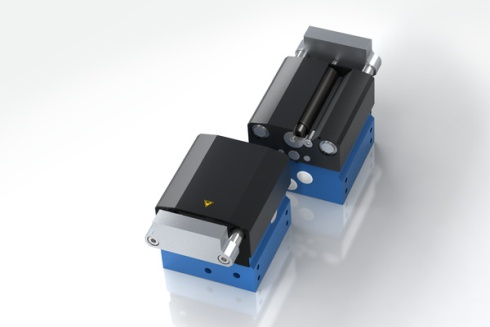

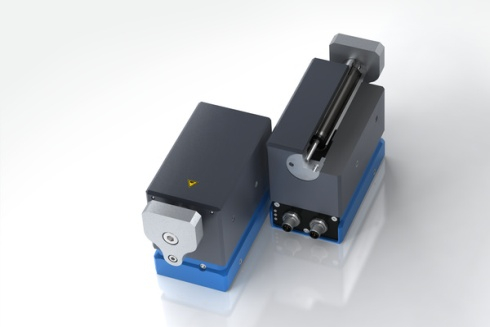

Electric Pallet StoppersPneumatic Pallet Stoppers

Perfect for safe and quiet operation

ACE electrically controlled separators come in four product families and cover a mass range from 0.25 kg up to 600 kg. The fact that these separators can manage without compressed air results in numerous benefits:

The positive aspects include less noise, greater environmental protection and higher effi ciency. Electric models also work intelligently due to their sophisticated technology because they are self-compensating within larger weight ranges. The individual models are available with a 2x5-pin M12x1 connector, which can be attached to separators and cabled to a PLC. All in all, this provides a very convenient solution thanks to a reduced requirement for maintenance.

|

P-E600Impressive: with an integrated ACE shock absorber for maximum accumulated loads up to 600 kg These electrically-operated ACE modules reliably stop even large masses, among other things using the built-in ACE shock absorber. A guarantee for quiet and safe operation. |

P-E20Small and delicate – for accumulated loads from 0.25 kg up to 20 kg These are the smallest, electrically-operated damping modules offered by ACE and are optimised for stopping lighter masses. They are used for the transfer of sensitive products at high speeds. |

|